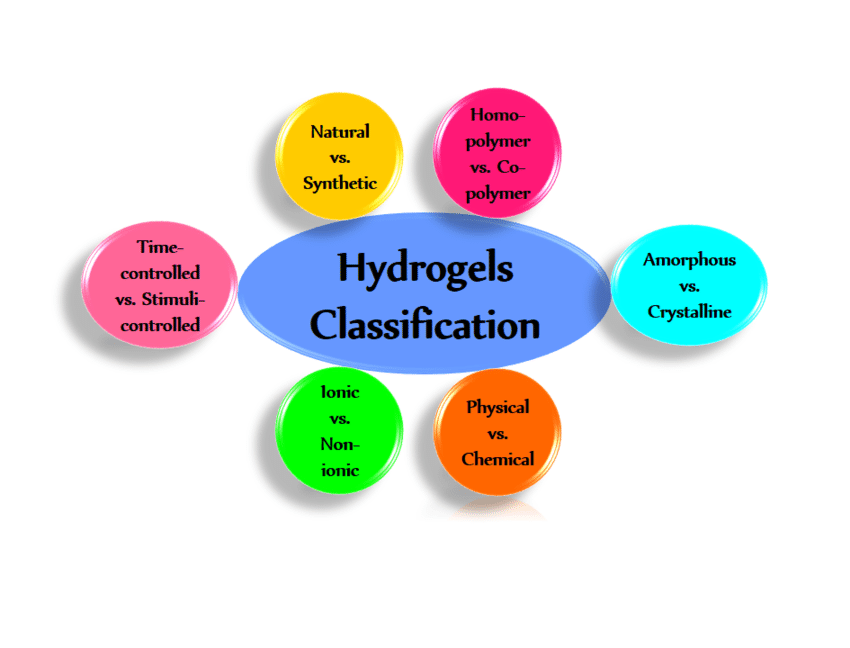

Hydrogels, three-dimensional hydrophilic polymer networks, are widely studied for their remarkable ability to absorb water and respond to environmental stimuli. Their applications span from medical sciences to industrial purposes due to their biocompatibility and versatility. Below, we explore their classification and diverse applications.

Types of Hydrogels Based on Cross-Linking

Hydrogels are broadly divided into two categories i.e. chemically cross-linked hydrogels that exhibit permanent linkages and physically cross-linked hydrogels that exhibit linkages which are produced naturally due to the tangles and various other interactions present in the polymeric chain.

Physically Cross-linked Hydrogels:

Hydrogels exist in nature and are reversible due to physical entanglements between networks. Because of their loose chain ends and chain loops, no homogeneity could happen. Physical crosslinking through the production of stereo-complexes forms dextran, poly(lactic acid), and polyethylene glycol,

Which may be further considered for medicinal purposes. H-bonding is the physical cross-linking mechanism used in the majority of hydrogels based on cyclodextrin, hyaluronic acid, chitosan, and alginate. Alginate is used to make the outer layer of capsules, and heat-induced aggregation or maturation are the processes that crosslink it.

Chemically Cross-linked Hydrogels:

End-functionalized macromeres are polymerized and covalently cross-linked to create these hydrogels. To chemically crosslink the hydrogels, substances such as glutaraldehyde, formaldehyde, and di-aldehydes are employed. Through its hydrated porous structure, hydrogel’s capacity to absorb water is further enhanced by chemical crosslinking.

Hydrogels based on polysaccharides can undergo chemical crosslinking. Physically cross-linked hydrogels are considered mostly over chemically cross-linked hydrogels due to their non-toxic effect on the environment. Hydrogels also exhibit various properties with respect to their crosslinking ratio as it affects their swelling behavior.

Higher the crosslinking ratio present in hydrogels, more compact the structure and lesser the swelling. Similarly, the low crosslinking ratio will lead to soft polymeric structures with more swelling capacity. Therefore, many specific properties of hydrogels can be altered by modifying their crosslinking patterns.

Comparison of Physically and Chemically Cross-Linked Hydrogels

| Aspect | Physically Cross-Linked | Chemically Cross-Linked |

|---|---|---|

| Formation Mechanism | Natural entanglements and interactions | Covalent bonding using chemical agents |

| Reversibility | Reversible | Permanent |

| Environmental Impact | Non-toxic | Potentially toxic due to chemicals |

| Applications | Biocompatible uses, e.g., capsules | Structural uses with enhanced strength |

2. BASED ON ELECTRIC CHARGE:

Hydrogels may be categorized into four groups on the basis of presence or absence of electrical charge located on the cross-linked chains:

(a) Nonionic (neutral)

(b) Ionic (including anionic or cationic)

(c) Amphoteric electrolyte (ampholytic) containing both acidic and basic groups

(d) Zwitterionic (polybetaines) containing both anionic and cationic groups in each structural repeating unit. [2]

3. BASED ON POLYMERIC COMPOSITION:

Homopolymeric hydrogels:

Homopolymeric hydrogels are referred to polymer network derived from a single species of monomer, which is a basic structural unit comprising of any polymer network. Homopolymers may have cross-linked skeletal structure depending on the nature of the monomer and polymerization technique.

Copolymeric hydrogels:

Copolymeric hydrogels are comprised of two or more different monomer species with at least one hydrophilic component, arranged in a random, block or alternating configuration along the chain of the polymer network.

Multipolymer Interpenetrating polymeric hydrogel:

Multipolymer Interpenetrating polymeric hydrogel (IPN), an important class of hydrogels, is made of two independent cross-linked synthetic and/or natural polymer component, contained in a network form. In semi IPN hydrogel, one component is a cross-linked polymer and other component is a non-cross-linked polymer.

HYDROGEL PRODUCT SENSITIVE TO ENVIRONMENTAL CONDITIONS:

As was previously noted, hydrogels are three-dimensional cross-linked hydrophilic polymer networks that have the ability to reversibly swell or de-swell in water while holding a sizable volume of liquid when swelled.

When the external environmental circumstances change, hydrogels can be engineered to respond in a controlled way, either by contracting or expanding. In response to a wide range of chemical and physical stimuli, such as pH, solvent composition, ionic strength, and molecular species, they may exhibit dramatic volume transitions.

Physical stimuli include temperature, electric or magnetic field, light, pressure, and sound. The hydrogel may experience such severe swelling or de-swelling in reaction to changes in its external environment that the phenomenon is known as volume collapse or phase changeover. [2]

Synthetic hydrogels have been a field of extensive research for the past four decades, and it still remains a very active area of research today.

APPLICATIONS OF HYDROGELS:

Numerous fields make use of hydrogels. This is because of their unique architectures and suitability for various usage scenarios. Because of their water content, hydrogels are flexible enough to be used in a variety of settings, from industrial to biological.

Their chemical behaviour in biological environments can also be nontoxic, which broadens their applications into the medical sciences. Additionally, the materials used to produce them are biocompatible.

The following is a list of some of the main uses for hydrogel.

Medical Dressing:

The most common conditions seen in hospitals are trauma and trauma infection. Medical dressings can help wounds heal by absorbing wound exudate fluid and serving as a protective barrier over wounds.

Hydrogel dressings are a great option for medical dressings because of their good flexibility and biocompatibility, ability to absorb liquid well, and ability to create a moist environment for tissue regeneration.

Additionally, the slip elastic state of the hydrogel helps to effectively prevent secondary injury caused by wound adhesion.

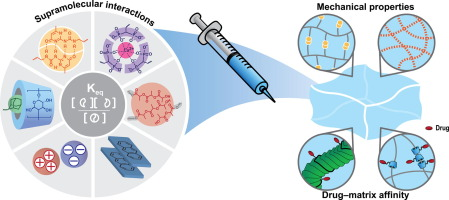

Delivery Of Drugs:

Drug delivery systems are technologically advanced devices designed to administer therapeutic drugs with precision and/or with controlled release.

Hydrogels are more useful in the field of drug delivery carriers because they can be used to store drugs, control the rate of drug release and drive the release, regulate the hardness and strength of formulations, promote decomposition, and mask the odour of pharmaceuticals.

Pulp Regeneration:

By cultivating pulp stem cells in vitro and implanting them on a biocompatible, absorbable, degradable biological scaffold, pulp regeneration is the application of tissue engineering principles. This process induces pulp stem cells to form pulp-dentin complexes and pulp-like tissues, which are then used to repair damaged pulp tissue and restore its physiological function.

Before gelation, the pulp chamber and root canal can be completely filled with the fluid by injecting the hydrogels that have been manufactured in injectable form. The hydrogel that is produced when the gelation process is complete sticks tightly to the surrounding tissue and is a good choice for use in pulp regeneration research.

Furthermore, the cells are encapsulated in the hydrogel, which subsequently goes through a sol-gel transition. This allows the cells to be distributed more uniformly inside the gel and may address the issue of exogenous cells in pulp regeneration that are challenging to penetrate deeply into the root canal scaffold.

Cardiac Restoration:

One of the most common illnesses that endanger people’s health is myocardial infarction. Heart failure results from the necrosis and scarring of a high number of myocardial cells following myocardial infarction. Due to its poor success rate, direct heart transplantation as a treatment for cardiac repair is influenced by the quantity of donors and rejection responses.

As a result, cardiac repair by cell transplantation is a more successful treatment for heart failure; yet, its broad clinical applicability is severely limited by the poor retention rate and low survival rate of cells following transplantation.

A wide range of naturally occurring or artificially generated polymers may be combined to create hydrogels, which are three-dimensional polymer networks with a high water content.

Because of these properties, hydrogels can be used as a vehicle for cell transplantation, simulating the extracellular matrix environment and enabling tissue regeneration as well as cell survival, proliferation, differentiation, and migration.

In addition to having biocompatibility, low immunogenicity, high permeability, and tunable mechanical properties, injectable hydrogels offer transplanted cells a better environment for survival.

They are also a crucial part of cardiac tissue engineering and can be infused into the myocardium via catheter for minimally invasive treatment.

Neural Tissue Repair:

Axonal continuity disruption, distal nerve fibre degeneration, and neuronal death are the results of peripheral nerve injury (PNI), which impairs a patient’s ability to carry out daily activities and results in loss of motor, sensory, and other autonomic functions.

Using artificial biomaterials and autologous nerves for bridging repair is the classic surgical strategy to treating peripheral nerve injury (PNI); however, the restricted supply of autonomic nerves and their mismatch in size restrict its utilisation.

Tissue scaffolds have the potential to serve as both a nerve cell growth carrier and a delivery system for neuropharmaceuticals, so resolving the issue of autologous nerve in therapeutic nerve repair.

A popular class of highly biocompatible materials for brain tissue regeneration applications recently are natural polymer hydrogels, which mimic the extracellular matrix environment of humans.

Its mechanical characteristics, like its hardness and viscoelasticity, are comparable to those of human nerve tissues. Additionally, the dense, three-dimensional structure that is created after swelling can stimulate the growth of new nerve cells. Finally, bioactive substances can be used to prepare a hydrogel neural tissue scaffold that has the ability to release drugs slowly.

Furthermore, by promoting nerve axon development, orienting cells, and filling in injured neural gaps, the natural polymer hydrogel may be employed as a substrate for cell culture to treat peripheral nerve injury.

Repairing The Bone Tissue:

In order to accomplish bone tissue repair and regeneration, efficient treatment approaches are required since bone abnormalities brought on by ageing, illness, trauma, and other circumstances are exceedingly damaging to the human body.

Although bone grafting is a valuable treatment for bone abnormalities, its use has been restricted due to a paucity of sources for bone grafting material, the unsoundness of donor bone tissue for allogeneic bone grafting, and the possibility of infection and sequelae.

Together with the benefits of regular hydrogels, stimulus-responsive hydrogels can sense external physicochemical stimuli like light, pH, temperature, and magnetic fields.

These stimuli can then cause changes in the hydrogel’s three-dimensional shape and solid-liquid phase state, which can lead to qualities like injectability, self-healing, and shape memory.

These hydrogels can be implanted into damaged tissues to heal bone tissue damage and facilitate functional restoration by including active cells and cell growth factors. [4]

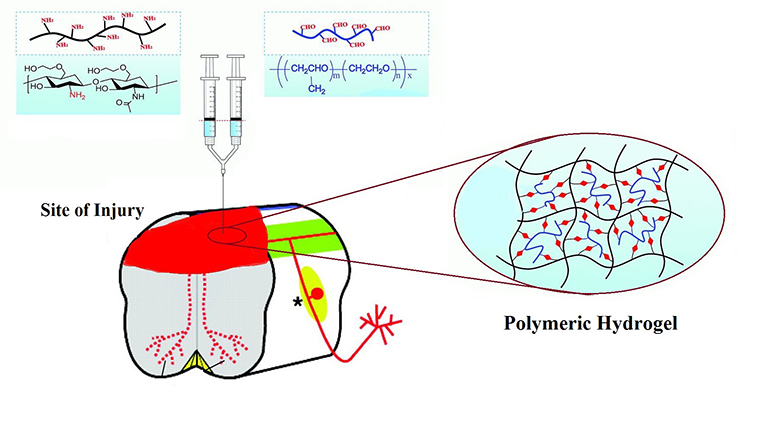

Repairing Spinal Cord Injuries:

Damage to the spinal cord that results in either temporary or permanent alterations to its function is referred to as a spinal cord injury (SCI). The majority of SCI patients have severe aftereffects such persistent pain and tetraplegia.

Although mesenchymal stem cell (MSC) transplantation is a valuable therapy option for spinal cord injuries, its continued use in clinical settings is restricted by the poor transplantation survival rate. Because hydrogel materials are biocompatible and biodegradable, they are frequently utilised in tissue engineering applications.

Combining MSCs with hydrogel has the potential to repair spinal cord injuries (SCIs) by stabilising the inflammatory environment at the lesion site, loading MSCs to deliver them in situ to the injured area for repair, and creating an environment that is conducive to the regeneration of the injured tissue.

Healing of Cartilage Degradation In Osteoarthritis:

Osteoarthritis is a degenerative disease in which the immune system and other processes cause long-term inflammation of cartilage tissue, ultimately resulting in cartilage destruction. For cartilage tissue healing, tissue engineering which uses biological scaffolds, seed cells, and advantageous growth factors has emerged as the most promising approach.

The extracellular matrix, however, causes massive cell death due to inflammation and inadequate support after seed cell transplantation, and cartilage repair does not produce the desired results. Therefore, the biological scaffold must be biocompatible and bioresorbable, support cell growth and differentiation, provide an appropriate mechanical environment, and permit the transport of cellular nutrients.

Hydrogels are significant biomaterials in the biomedical area because of their exceptional biocompatibility, which reduces tissue damage and inflammatory responses. Hydrogels are cross-linked hydrophilic polymers.

All connective, epithelial, and neural tissues contain hyaluronic acid, which is a crucial part of the extracellular matrix that promotes cell migration and multiplication. Hyaluronic acid hydrogels, which include the benefits of both, are therefore frequently employed in osteoarthritis cartilage repair due to their high biocompatibility, biodegradability, and low immunogenicity.

Delivery Of Interventions via hydrogel:

One innovative use of hydrogels in the biomedical industry is the delivery of treatments using hydrogel-mediated systems. A thin layer of hydrogel coating is created on the inside surface of blood arteries by the interfacial in situ polymerization technique of hydrogel.

This isolates the contact between blood and damaged vessel walls and prevents platelet deposition, thrombosis, and new endothelial growth. Furthermore, by providing bioactive elements, the bioactive hydrogel coating can facilitate endothelial repair and restore the blood vessel’s normal function.

REFERENCES:

1. Kaith BS, Singh A, Sharma AK, Sud D. Hydrogels: synthesis, classification, properties and potential applications—a brief review. Journal of Polymers and the Environment. 2021 Dec;29(12):3827-41.

2. Ahmed EM. Hydrogel: Preparation, characterization, and applications: A review. Journal of advanced research. 2015 Mar 1;6(2):105-21.

3. Bahram M, Mohseni N, Moghtader M. An Introduction to Hydrogels and Some Recent Applications [Internet]. Emerging Concepts in Analysis and Applications of Hydrogels. InTech; 2016. Available from: http://dx.doi.org/10.5772/64301

4. https://www.biochempeg.com/article/244.html

Read Also